In last month’s column I wrote about the process of pulling a vacuum on refrigerating systems and highlighted some good practice points for care of the vacuum pump and how it is connected to the system for best effect. Here are some more tips for maximizing the benefit and avoiding some horrible pitfalls.

Don’t use a gauge manifold to connect the vac pump and gauges to the system. Firstly, the hoses are too small diameter and too long to enable the best effect to be achieved. Secondly, the gauge needs to be on a different part of the system in order to indicate the true level of

vacuum that has been achieved.

Do make sure to use a sufficiently accurate vacuum gauge for this purpose. It needs to tell the difference between a system holding a vacuum of 29.7 inches of mercury and 29.8 inches of mercury. The gauges on a manifold are just not that accurate. Nowadays it is possible to buy a simple electronic vacuum gauge for less than $100 and a high quality calibrated electronic gauge for less than $1,000. The saving in time spent messing around will pay for this many times over.

By the way, do understand the many and varied units used to measure vacuum and be very precise in how you use them, especially when specifying vacuum procedures to other people. The units I used above, inches of mercury, are particularly devilish because they measure from the other end. Zero inches of mercury (sometimes abbreviated as “in Hg”) is atmospheric pressure and 29.92 inches of mercury is absolute vacuum. The higher the number, the lower the pressure. I prefer to use the unit “Torr” although it is neither Systeme International (SI) nor inchpound (I-P). Named after the Italian scientist, Torricelli, a Torr is equivalent to the pressure required to raise mercury by 1 mm (0.039 in.) in a Fortin barometer. The inch of mercury (whichever end of the scale you measure from) has the same origin—nominal atmospheric pressure is 760 Torr or 29.92 inches of mercury absolute. I also recommend avoiding the “micron” as a measurement of pressure. Strictly speaking this should be understood to be one millionth of a metre of mercury (in other words a “milliTorr”) but there always seems to be too much room for confusion about whether it is a micrometer or a microinch. The reason I like the unit of Torr is that it is absolutely unambiguous.

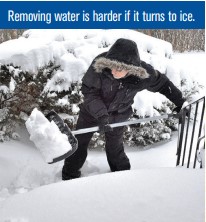

To make sense of the whole vacuum process it is essential to understand what you are trying to achieve (which is not always the same thing from job to job). As mentioned last month, removal of air (or pressure test gas) is one reason but removal of moisture or even free water

is also important. A small amount of water in the system will hinder the vacuum process because it will start to boil when the pressure gets down to the saturation point for the temperature of the water. This is obvious if you know what to look for because the pressure will plateau at a level equivalent to the prevailing temperature. However if there is a lot of free water inside the system it could take weeks to boil it dry using the vac pump. On the other hand, if the geometry of the system enables the pressure to fall well below the saturation point and it gets down to the triple point of water (6.1 mBar abs, 4.5 Torr or 29.74 in Hg) then some of the water will freeze and it is much more difficult to remove it through the vac pump. Even worse, I was once involved in a project where evaporators were being installed inside an existing cold store. The evaporators were badly contaminated with water but it froze before the vacuum was pulled, so everything seemed fine until the system was charged and the water flooded back to the receiver.